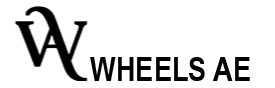

Forged Wheels vs Cast Wheels – Which One Survives UAE Heat Better?

The UAE is one of the toughest environments in the world for wheels. The mix of 50°C summers, sudden temperature shifts, high-speed highway driving, and rough desert surfaces puts enormous pressure on the metal. That’s exactly why so many drivers search for “forged wheels UAE” — people want wheels that can survive this climate without cracking, bending, or fading.

But the big question is still the same:

Are forged wheels really stronger than cast wheels in UAE heat?

Let’s break it down in a simple, technical, and UAE-specific way.

⸻

1. Manufacturing: Why It Matters in UAE Conditions

Cast Wheels (Gravity Cast / Low-Pressure Cast)

Cast wheels are made by pouring melted aluminum into a mold and letting it cool.

This process creates:

• More air pockets inside the metal

• Lower density

• Lower strength

• Higher flexibility at high temperatures

In normal climates, cast wheels are fine. But in UAE conditions, those small air pockets become weak points that can expand with heat and crack over time.

⸻

Forged Wheels (6061-T6 Aerospace Grade)

Forged wheels start with a solid block of 6061-T6 aluminum, then undergo:

• High heat treatment

• Extreme pressure shaping (up to 10,000 tons)

• Precision CNC machining

Result:

• No internal air pockets

• Very dense metal structure

• 3–4x stronger than cast

• Lower risk of cracking or bending

This is why forged wheels are the preferred choice for exotic cars, high-speed drivers, and off-roaders in the Gulf.

⸻

2. Heat Resistance: Why Forged Wins in the UAE

UAE summer heat reaches 50°C outdoors.

On highways, wheel temperature easily reaches 150–200°C due to friction and braking.

Cast wheels expand unevenly because of their weak structure. This can lead to:

• Micro-cracks

• Loss of shape

• Bending under load

• Paint fading or peeling

Forged wheels, especially 6061-T6 heat-treated, handle temperature change much better.

The T6 hardening process helps them:

• Maintain strength

• Resist deformation

• Avoid micro-cracks

• Stay stable at high speed

This is why professional tuners and performance shops in Dubai always recommend forged wheels to their customers.

⸻

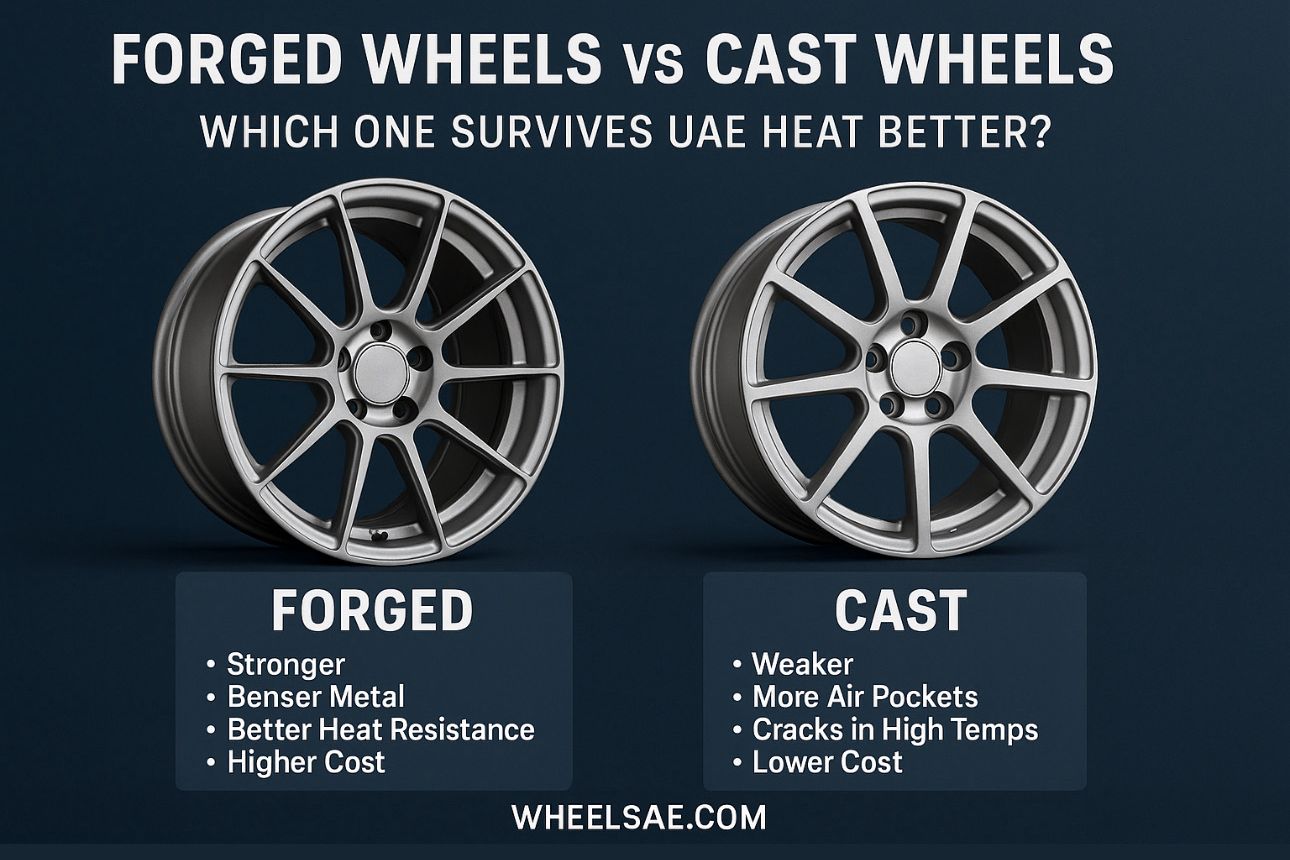

3. Why Cast Wheels Crack More Often in the UAE

You’ve probably seen photos of wheels cracking on Sheikh Zayed Road or E311.

Most of the time, they’re cast wheels.

Reasons:

• Cast aluminum is softer

• Internal air bubbles expand under heat

• Sudden impact (speed bumps, potholes) weakens the wheel

• Repeated heat cycles cause metal fatigue

In comparison:

• Forged wheels distribute impact energy more evenly

• No air bubbles exist inside the metal

• They maintain structural integrity even at extreme temperatures

This is why luxury brands like Ferrari, Lamborghini, Porsche, and high-performance SUVs in Dubai mostly run forged setups.

⸻

4. 6061-T6 Forged Wheels: Tested in UAE Conditions

At WheelsAE, our forged wheels are made from 6061-T6 aircraft-grade aluminum — the same alloy used in aerospace engineering and military components.

Why 6061-T6 is ideal for UAE:

• High tensile strength

• Excellent heat resistance

• Low risk of structural fatigue

• Perfect for fast, heavy, and powerful cars

• Resistant to desert corrosion and humidity

Many customers using WA-F series forged wheels report:

• Better driving stability

• Less vibration

• No cracking even after long-term UAE heat exposure

• Better performance at high speeds

You can explore some models here:

👉 https://wheelsae.com/product-category/custom-forged-wheels/

⸻

5. Weight Difference: Why Forged Improves Performance

Forged wheels are lighter than cast wheels while being stronger.

This gives UAE drivers benefits like:

• Faster acceleration

• Better braking

• Improved fuel efficiency

• Sharper steering response

• Reduced strain on suspension

Lightweight wheels also help EVs like Tesla Model S/X/Y increase range because they reduce rotating mass.

⸻

6. Safety at High Speed (Dubai–Abu Dhabi Drivers Read This)

The UAE has some of the fastest highways in the world.

When driving at 140–180 km/h, wheel quality becomes a major safety factor.

Cast wheels can deform or crack under:

• Heat expansion

• High-speed cornering

• Sudden braking

• Heavy loads

Forged wheels, due to their dense structure, stay rigid and stable — keeping the car balanced at high speeds. This is why performance enthusiasts and SUV drivers trust forged wheels far more.

⸻

7. Off-Road Conditions: Forged Wheels Always Win

Drivers of:

• Patrol Y61/Y62

• Land Cruiser 200/300

• Wrangler / Gladiator

• FJ Cruiser

…know how harsh the desert can be.

Sand dunes, bumps, rocks, side hits — all of these can crack or bend cast wheels.

Forged wheels are strong enough to survive heavy dunes, jumps, and side impacts without structural damage.

For heavy off-roading, beadlock forged options are also available in our collection.

⸻

8. Paint & Finish Durability in UAE Heat

Heat destroys paint — especially cheap cast wheel finishes.

Common problems:

• Clear coat peeling

• Color fading

• Oxidation

• Sand abrasion

Forged wheels support:

• Higher-quality powder coat

• Ceramic finishes

• More durable clear coats

They stay shiny and clean much longer in UAE weather.

⸻

9. Cost Comparison – Is Forged Worth It?

Yes, forged wheels are more expensive.

But in UAE conditions, they are more cost-effective long-term.

Cast wheel total cost (UAE reality):

• Frequent bending

• Cracks → replacement

• Paint damage

• High maintenance

Forged wheel total cost:

• No bending

• Extremely low crack risk

• Better finish durability

• Long lifespan

You pay once — and enjoy safety and performance for years.

⸻

Which One Survives UAE Heat Better?

Forged wheels win — every time.

For the UAE’s extreme heat, fast highways, and desert conditions, forged wheels are the safest, strongest, and most durable option.

If you want the best performance, durability, and custom design, explore WheelsAE’s forged wheel lineup:

👉 https://www.instagram.com/wheels__ae/

⸻