wheel manufacturing in China

🔧 Introduction: Why China Is the Hub for Wheel Production

China has rapidly become the global epicenter of aftermarket and OEM wheel manufacturing. With advanced factories, skilled engineering teams, and a full vertical supply chain — from aluminum smelting to CNC machining — it’s no surprise that even premium global brands manufacture their wheels in China.

At Wheels AE, we work directly with top-tier Chinese manufacturers to design, test, and import wheels that are tailor-made for Gulf conditions. In this article, we’ll walk you through the entire process of wheel manufacturing in China, from early 3D design to doorstep delivery in Dubai.

⸻

🎨 Step 1: 3D Wheel Design and Engineering

Every wheel starts with a vision.

Designers use software like SolidWorks, AutoCAD, or CATIA to:

• Sketch unique spoke patterns

• Set correct PCD, offset, and center bore

• Simulate airflow for brake cooling

• Run stress tests with virtual loads (FEA)

This stage is crucial because it determines:

• Fitment on specific cars (e.g. 5×114.3 for Tesla/Mustang)

• How much the wheel will weigh

• Where the material will absorb shock under load

👉 Our exclusive WA Series is co-designed between Dubai and China using real Gulf vehicle data.

⸻

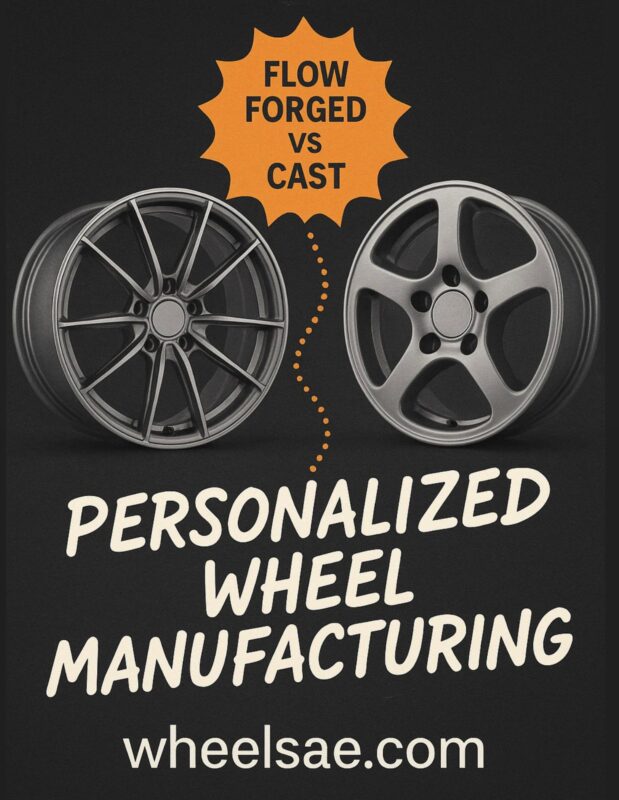

🔩 Step 2: Mold Creation for Casting or Forging

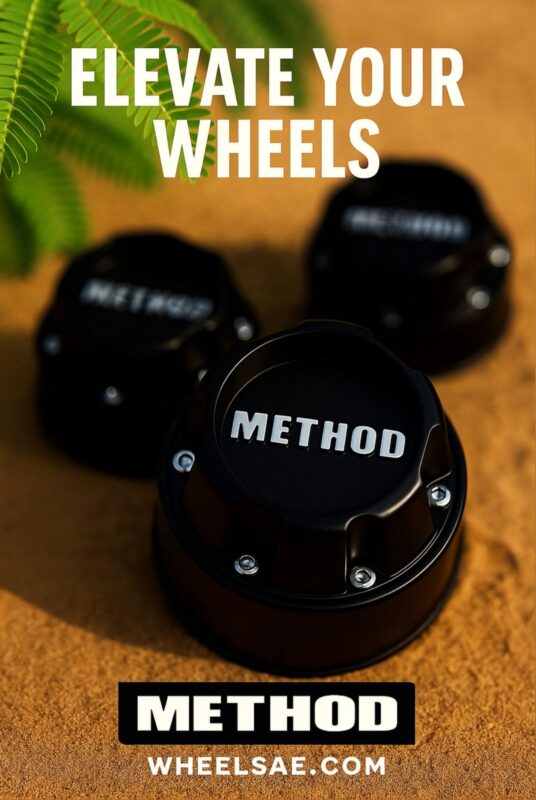

After finalizing the design:

• Cast wheels require custom molds made of steel, where molten aluminum is poured and shaped.

• Forged wheels start from aluminum billets (huge solid cylinders), then compressed under thousands of tons of pressure in custom molds.

Forged molds are more complex, durable, and expensive — but they allow:

• Sharper details

• Thinner, lighter spokes

• Superior strength in high-heat Gulf environments

⸻

🏭 Step 3: Raw Manufacturing – Casting or Forging

Depending on the type of wheel:

Cast Wheels:

• Molten aluminum is poured into molds (gravity or low-pressure cast)

• The aluminum is allowed to cool and harden

• The result: a solid wheel shape, ready for machining

Forged Wheels:

• Aluminum billet is heated and pressed into the mold

• The material structure is aligned, making it incredibly strong

• These wheels are lighter and more resistant to cracking under UAE heat

🔍 Many of the best-selling wheels in Dubai — like our WA-3052, WA-3044 — are forged or flow-forged in China.

⸻

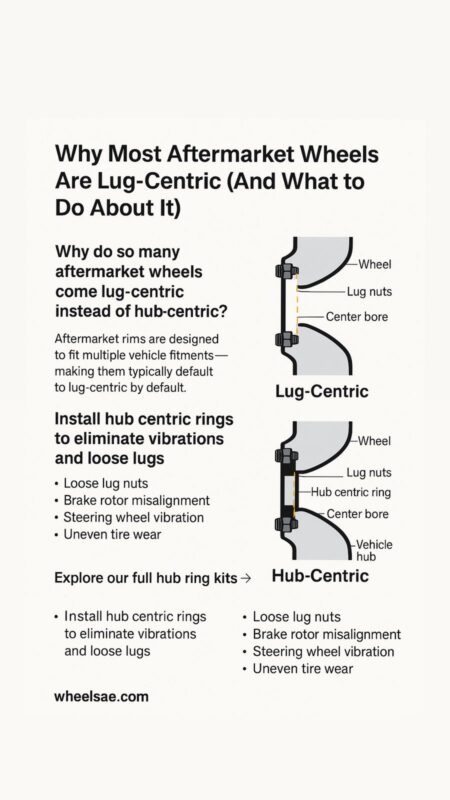

⚙️ Step 4: CNC Machining and Milling

After forming the wheel blank, CNC machines carve:

• The bolt holes (e.g. 5×114.3 or 6×139.7)

• The center bore (e.g. 73.1 mm)

• The backpad (adjusting offset)

• Branding, logos, and sometimes decorative details

Ultra-precise CNC milling ensures:

• Zero vibration

• Hub-centric accuracy

• Flush fitment with no rubbing

Every Wheels AE wheel is made to hub-centric specs for UAE cars.

⸻

🎨 Step 5: Finishing – Painting, Powder Coating, or Anodizing

This is where design comes to life.

Chinese factories offer:

• Gloss, matte, or satin finishes

• Anodizing (for metallic tones like bronze or gold)

• Diamond-cut face

• UV-resistant powder coat (ideal for UAE sun)

We reject any wheels that use low-quality paint or chrome plating, as they can’t withstand Gulf summer conditions.

✅ Our WA-BL series is finished with sand-resistant matte coatings, perfect for off-road SUVs.

⸻

🧪 Step 6: Quality Control (QC) and Testing

Before any wheel leaves China, it goes through:

• X-ray testing to check for internal voids

• Balance and runout tests

• Salt spray tests for corrosion resistance

• Impact tests simulating potholes or curb strikes

• TUV and JWL certifications

Only the wheels that pass these rigorous checks are packed and labeled “Wheels AE Approved.”

⸻

📦 Step 7: Packaging and Shipping to Dubai

Packaging is crucial for long-distance transit. Wheels are:

• Double-wrapped in foam + bubble

• Sealed in cardboard with corner guards

• Shipped via container or air cargo (depending on urgency)

From China to Dubai:

• Sea freight = ~20–25 days

• Air freight = 3–7 days

• Clearance handled through Jebel Ali or Dubai Customs

We maintain stock in Dubai to ensure local delivery within 24–48 hours for most orders.

⸻

🚚 Step 8: Delivery to Customers Across the UAE

Once in Dubai, wheels are:

• Stored in our warehouse in temperature-controlled zones

• Matched with tires if requested

• Delivered to Dubai, Sharjah, Abu Dhabi, or shipped GCC-wide

We also provide:

• Bolt kits

• TPMS sensors

• Hub rings & spacers (if needed)

📦 You can also pick up in-store or request fitment service at one of our partner garages.

⸻

🧭 Why We Trust Chinese Manufacturing (But Not All of It)

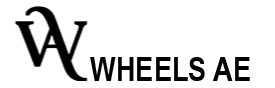

Not all factories are equal.

We’ve spent years filtering:

• Factories with poor tolerances

• Fake forged labels

• Weak painting that fades in sun

• Mold defects

We now work exclusively with TUV, ISO, and JWL-certified manufacturers, many of whom supply wheels for global car brands.

Because our standards match Dubai drivers’ needs:

✔ High-speed safety

✔ Heat durability

✔ Visual excellence

✔ Legal RTA compliance

⸻

🏁 Final Thoughts: The Journey from Factory to Fast Lane

The journey of a wheel is long — from design software in China to your driveway in Dubai.

Every curve, coating, and bolt hole has a story:

• Born from precision

• Forged in heat

• Delivered with confidence

Whether you’re upgrading your Tesla, muscle car, or SUV — Wheels AE brings you wheels made for the region, by people who understand it.

⸻

Want to See It in Action?

📸 We’ll be publishing behind-the-scenes video tours of factories in China soon on our Instagram:

👉 @wheels_tire.ae

🛒 Browse all available wheels:

👉 wheelsae.com/shop

📦 Need bulk import or private labeling?

📧 Email us directly or message on Instagram.